Many customers and junior installers believe that installing a stone is a dirty process. It really happens, if the stonemason has a small experience and works incorrectly. An experienced specialist predicts in advance how much dust and dirt will be formed during installation, notifies the customer about it and actions needed. But most importantly is to effectively minimize pollution, whether it is a living room, kitchen or bathroom. Often the repair of the house is bypassed even without the removal of furniture or the closing of items.

Many customers and junior installers believe that installing a stone is a dirty process. It really happens, if the stonemason has a small experience and works incorrectly. An experienced specialist predicts in advance how much dust and dirt will be formed during installation, notifies the customer about it and actions needed. But most importantly is to effectively minimize pollution, whether it is a living room, kitchen or bathroom. Often the repair of the house is bypassed even without the removal of furniture or the closing of items.

Practical example

Let’s look at an example from real life when stone installing is not so dirty as it seems at first. In the kitchen of the apartment, the stonemason installed a benchtop consisting of three sections, occupying two corners, almost along the entire perimeter. The hosts wanted to use a maximum of useful space for cooking, dishes storing and other kitchen affairs. In the factory some parts of benchtop are made rectangular, so they have to be glued together. This procedure is also quite dirty with inept performance.

Working in a factory

All measurements were made by the professional earlier with special quality tools. Then, qualifies machine operators in the workshop cut all the necessary grooves and holes by high-precision machines. These process allows to eliminate using on the spot the grinder, jigsaw and drill that drastically reduces pollution. Mineral dust does not rise into the air. The installation of a stone window sill can be simpler, because communications cannot pass through it. And a slight error in size does not lead to critical consequences. While installation of stone benchtops in the bathroom or in the kitchen requires high accuracy.

Instalation in the house

The loaders delivered the finished benchtops, and the stonemasons began to install them. First, stone kitchen benchtops are laid on the kitchen cabinets and checked for level. Having established the correctness of the position of all parts of the table and checking that the top surface smoothly passed one into the other, the stonemasons begin to fit corners. Then they again check the level of all parts. It takes a few minutes because the factory stone benchtops have been made with high precision. It remains only to paste the details.

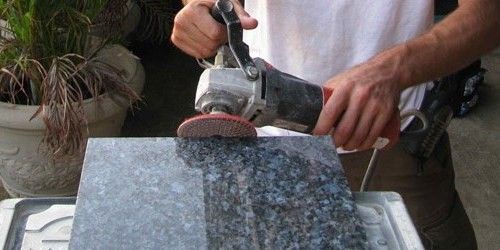

Stone polishing

The joints are copiously treated with acetone, so that no dust marks remained in them. The professionals apply the appropriate amount of glue. In this case a thick liquid slightly protruded at the top but insignificantly. Than parts are strengthened plates with clamps until complete glue polymerization. After solidification of the one or two-component adhesive composition in a half an hour, the clamps are removed.

The joints are copiously treated with acetone, so that no dust marks remained in them. The professionals apply the appropriate amount of glue. In this case a thick liquid slightly protruded at the top but insignificantly. Than parts are strengthened plates with clamps until complete glue polymerization. After solidification of the one or two-component adhesive composition in a half an hour, the clamps are removed.

Then followed the dirtiest part of the job – grinding the seams with an angular grinder. Primary one is with coarser grain, and finishing with fine. At this stage of the work performed it would be better if all the items in the room or in the kitchen have been previously covered with a protecting film.

The last stage is to fix a sink and cooktop. Since the silicone is used for these purposes, the dirt does not form. The installers wash the benchtop surfaces with acetone and completed the work. Under such a scheme by highly qualified stonemasons, the construction or renovation of a house passes easily and quickly, without much noise and dirt.